Bauxite, also known as alumina and monohydrallite, is mainly composed of aluminium oxide, specifically the hydrated alumina with impurities--- a kind of earthy mineral. It is white and offwhite and sometimes it presents isabelline and light red because of the iron content in it. The Moh's hardness is 1-3. The opaque bauxite is brittle, hard to fuse and insoluble in water. It is mainly used to produce aluminum, fireproofing products and abrasive substance. Besides it can be seen in such fields as military industry, spaceflight, telecommunication, instrument, machinery and medical machine production.

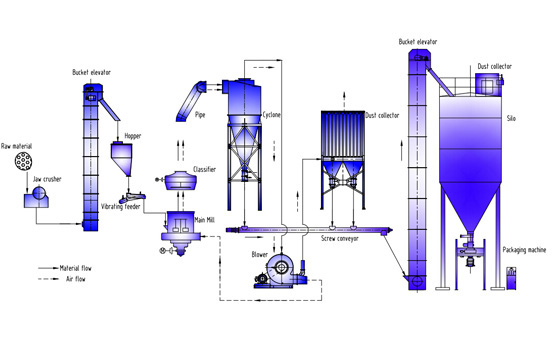

1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage: The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage:With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor and packed by powder filling tanker and automatic pack machine.