Coal, a kind of energy, is widely used in such fields as electricity, steel, textile, chemistry and metallurgy, etc.. Raw coal has sulfur and traditional coal blocks has low combustion ratio but high pollution. The hot topic of efficient use of coal attracts people's attention on efficient coal powder preparation for it has high combustion ratio and zero pollution.

| Fineness | Applications | Recommended Equipment |

| Around 60meshes | Surface coal. Processing humic acid | MTM,MTW |

| 180-200meshes | Processed into clean(efficient) coal powder. Used to blast furnace coal injection in steel plant; Used in Eco saving boiler combustion, achieving clean use and reducing pollution. | MTW,LM |

| 200meshes D90 | After being processed, coal powder can be transformed into flammable gas to increase combustion ratio, clean and pollution-free. | MTW,LM |

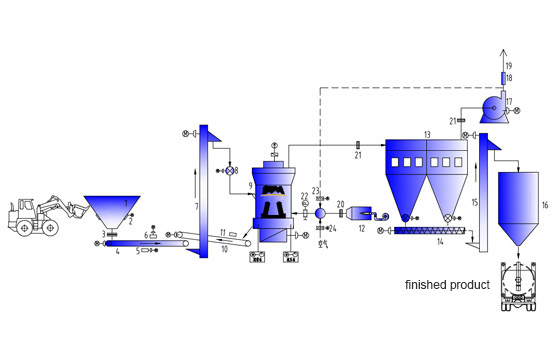

1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage:The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage: With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor.